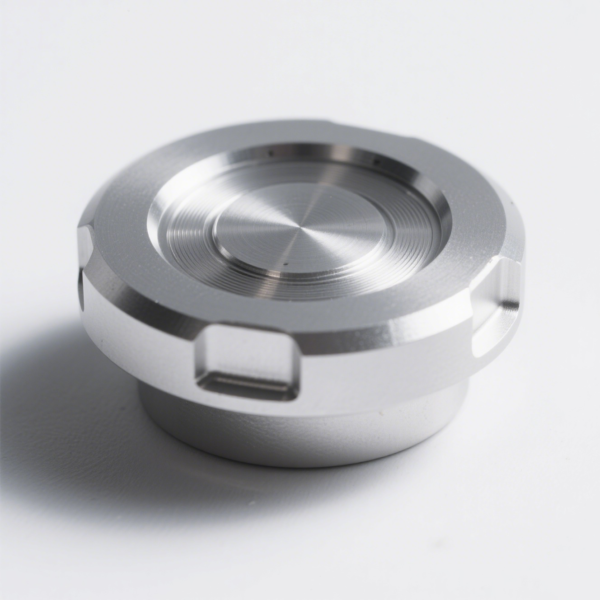

– Shenzhen Precision CNC Machining Services offers customized manufacturing solutions for a wide range of car accessories, utilizing advanced Computer Numerical Control (CNC) technology.

– These services focus on high-precision machining with tight tolerances, catering to diverse material needs and customization requests.

– The process involves removing material from a workpiece using automated, computer-controlled machinery to create the desired part.

Key Features

High Precision:

Shenzhen’s CNC machining capabilities ensure accuracy and precision, with tolerances as tight as 0.01-0.05mm, guaranteeing high-quality custom parts.

Material Versatility:

A wide array of materials can be used, including aluminum, brass, copper, stainless steel, and various alloys, allowing for diverse design possibilities.

Customization Options:

Services include various CNC machining processes such as milling, turning, drilling, and more, as well as surface treatments like anodizing, plating, and polishing, to meet specific customer needs.

Rapid Prototyping:

The service can produce prototypes quickly, allowing for design verification and adjustments before mass production.

Custom Part Creation:

CNC machining allows for the creation of unique parts that are not readily available, addressing specific requirements for car accessories.

Automotive Applications:

CNC machining is widely used in the automotive industry for various components like engine parts, gears, fasteners, and other mechanical parts.

Quality Assurance:

Certified by organizations like TUV, the service ensures adherence to international standards, assuring customers of reliable and high-quality parts.

CNC Technology:

CNC machining utilizes computer numerical control to automate the machining process, offering precision and efficiency

Reviews

There are no reviews yet.